From a purchaser's perspective, selecting the right scaffolding system is not only about meeting immediate project requirements, but also about long-term value, safety compliance, and operational efficiency. Among the many scaffolding solutions available, H-frame scaffolding—also known as frame scaffolding—remains one of the most widely used and cost-effective systems in the global construction market.

Its popularity is driven by a combination of simple design, reliable performance, and ease of use. For purchasers responsible for sourcing equipment for contractors, rental companies, or large construction firms, understanding what H-frame scaffolding is used for—and why it continues to be a preferred choice—is essential for making smart procurement decisions.

Overview of H-Frame Scaffolding

H-frame scaffoldingconsists of prefabricated vertical frames shaped like the letter “H,” connected by cross braces to form a stable working platform. The frames are stacked vertically and linked horizontally, creating a modular access structure that is easy to assemble and dismantle.

From a purchaser’s viewpoint, this standardized structure offers key advantages: predictable compatibility, fast installation, and straightforward inventory management. Compared with more complex modular systems, H-frame scaffolding requires less specialized training, reducing labor dependency and improving overall site efficiency.

Materials: Strength and Durability

One of the main factors influencing the performance and lifespan of H-frame scaffolding is material quality. Most high-quality H-frame systems are manufactured from structural-grade steel tubing, designed to handle the daily wear and tear of construction environments.

Steel Grade: Frames are commonly made from high-strength carbon steel, which provides a strong balance between load capacity and cost efficiency.

Tube Thickness: Thicker wall tubes improve rigidity and load-bearing performance, which is especially important for commercial and industrial applications.

Surface Treatment: H-frame scaffolding is often available in painted, powder-coated, pre-galvanized, or hot-dip galvanized finishes. Among these, hot-dip galvanization offers the best corrosion resistance and longest service life, making it the preferred choice for outdoor projects or rental fleets.

For purchasers, investing in better materials and surface treatments may result in a slightly higher upfront cost, but it significantly reduces long-term maintenance and replacement expenses.

Manufacturing Technology: Consistency and Safety

Modern H-frame scaffolding is produced using advanced manufacturing technologies that enhance consistency, safety, and overall product quality. Leading manufacturers utilize:

Automatic and robotic welding to ensure uniform weld strength and reduce human error

Precision jigs and fixtures to maintain accurate frame dimensions

Strict quality inspection processes, including load testing and weld inspections

From a purchaser's perspective, these technologies translate into more reliable products with fewer defects, smoother assembly on-site, and reduced risk of failures. This is especially important for companies managing large inventories or supplying scaffolding to multiple projects simultaneously.

Key Features That Drive Buyer Demand

frame scaffolding continues to be widely used because of several practical features that directly benefit purchasers and end users alike:

1. Easy and Fast Assembly

One of the biggest advantages of H-frame scaffolding is its simplicity. Workers can quickly erect frames and braces with minimal tools, reducing installation time and labor costs. For purchasers, this means improved productivity for contractors and faster project turnaround.

2. Cost-Effectiveness

Compared with modular systems like Ringlock or Cuplock, H-frame scaffolding typically has a lower initial purchase price. This makes it particularly attractive for:

Residential construction

Small to mid-rise commercial projects

Renovation and maintenance work

Rental scaffolding fleets

For budget-conscious purchasers, H-frame systems offer an excellent balance between affordability and functionality.

3. Wide Compatibility

H-frame scaffolding is highly standardized in many markets, allowing for compatibility with common accessories such as walk-through frames, guardrails, platforms, base jacks, and caster wheels. This flexibility helps purchasers manage inventory more efficiently and reduces the need for project-specific custom components.

4. Stability and Safety

When properly manufactured and installed, H-frame scaffolding provides a stable working platform. Features such as strong cross bracing, solid frame welding, and quality locking pins contribute to overall system safety. For purchasers, this means fewer safety incidents and stronger compliance with workplace safety requirements.

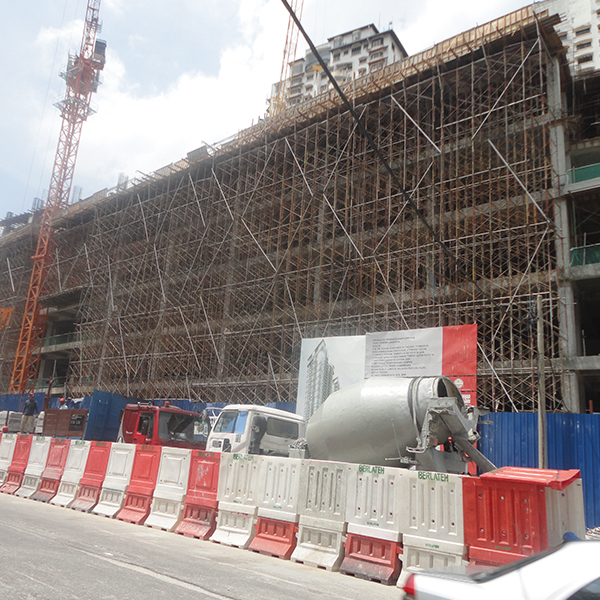

Typical Applications of H-Frame Scaffolding

From a purchaser’s point of view, H-frame scaffolding is valued for its versatility across a wide range of applications, including:

Residential Construction: Ideal for housing projects, exterior wall work, and roofing access.

Commercial Buildings: Commonly used for façade work, painting, plastering, and window installation.

Maintenance and Renovation: Well-suited for repair, retrofitting, and interior access projects.

Industrial and Warehouse Use: Frequently used for equipment maintenance and facility upgrades.

Rental Market: Due to durability and ease of use, H-frame scaffolding is a top choice for rental companies seeking high asset utilization.

These diverse uses make H-frame scaffolding a dependable, high-demand product for purchasers serving multiple customer segments.

Why Purchasers Choose ADTO Scaffold

Choosing the right supplier is just as important as choosing the right scaffolding system. ADTO Scaffold is a globally recognized manufacturer with over 25 years of experience in producing high-quality scaffolding and formwork systems.

From a purchaser's perspective, ADTO Scaffold offers several key advantages:

Use of high-grade steel materials for superior strength and durability

Advanced welding and manufacturing technology for consistent quality

Multiple surface treatment options, including hot-dip galvanization

Compliance with major international standards and certifications

Competitive factory-direct pricing

Customization options for different regional and project requirements

Reliable global logistics and professional after-sales support

By sourcing H-frame scaffolding from ADTO Scaffold, purchasers gain a reliable partner who can support both short-term project needs and long-term business growth.

Conclusion

H-frame scaffolding remains one of the most practical and widely used scaffolding systems in construction due to its simplicity, affordability, and versatility. From a purchaser’s perspective, it offers strong value through reliable materials, modern manufacturing technology, and user-friendly features that support a wide range of applications.

For purchasers seeking dependable quality, consistent supply, and long-term value, ADTO Scaffold stands out as a trusted supplier capable of delivering high-performance H-frame scaffolding solutions for today’s competitive construction market.