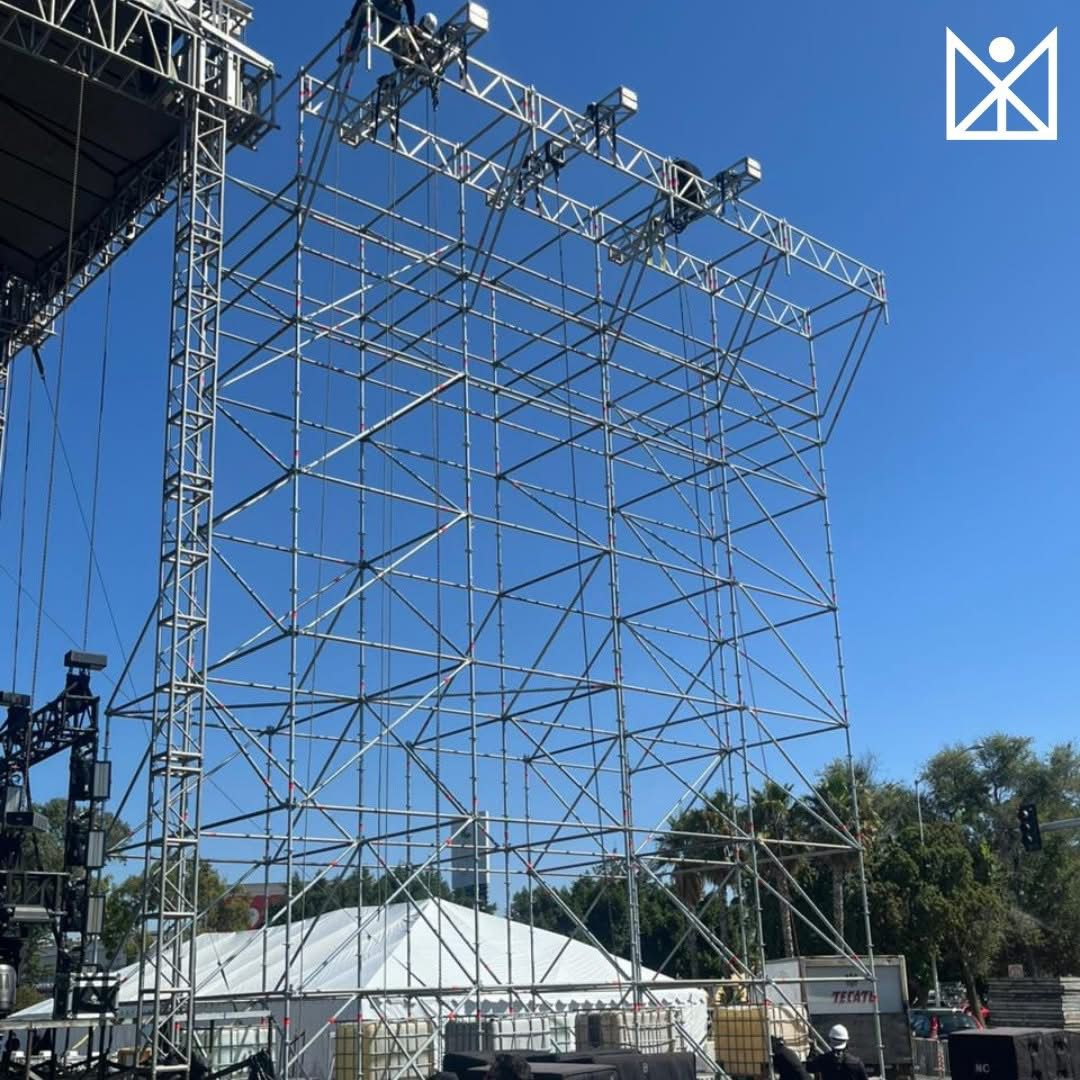

When it comes to construction, renovation, or industrial maintenance, modular scaffolding stands out as one of the most efficient and versatile systems on the market. Its standardized design, quick assembly, and high load-bearing capacity make it an essential tool for professionals around the world. However, as convenient as modular scaffolding is, it also presents serious risks if not handled properly. Safety should always come first — not only to protect workers but also to ensure the stability and efficiency of the entire project.

As a buyer or contractor, understanding the key safety precautions before setting up modular scaffolding can make a world of difference. Here are 10 essential safety tips to keep in mind — and why choosing a trusted supplier like ADTO Scaffold can help you work safely and efficiently every time.

1. Inspect All Components Before Assembly

Before beginning setup, always inspect every scaffold component — from vertical standards and ledgers to diagonal braces and platforms. Look for signs of corrosion, bending, cracks, or missing locking pins. Damaged components should never be used, as even a single weak connection can compromise the entire structure. A reliable supplier like ADTO Scaffold ensures that each modular component is manufactured with premium materials and strict quality control, reducing the risk of faulty parts.

2. Choose a Stable and Level Foundation

A scaffold is only as strong as its foundation. Always set up modular scaffolding on a firm, level surface that can bear the load of both the structure and workers. Use base plates or adjustable jacks to stabilize the scaffold on uneven ground, and never set it directly on soft soil without adequate support. A stable foundation prevents tilting, sinking, and structural failure.

3. Follow Manufacturer's Assembly Instructions

Every modular scaffolding system is designed with specific assembly guidelines and load ratings. It’s essential to follow these instructions carefully. Modular systems, such as ringlock or cuplock scaffolds, rely on precise connections and locking mechanisms to ensure safety. Avoid improvising or mixing components from different brands. With ADTO Scaffold, users receive clear assembly manuals and technical support to guarantee correct setup every time.

4. Use Proper Guardrails and Toe Boards

Falls are one of the most common construction site accidents. To prevent them, always install guardrails, mid-rails, and toe boards on all open sides of the working platforms. These components act as physical barriers against slips or accidental drops of tools and materials. Modular scaffolding systems from ADTO include custom-fit safety accessories that comply with international standards, offering maximum protection without compromising efficiency.

5. Never Exceed the Load Capacity

Every scaffold has a maximum load limit, which includes the weight of workers, tools, and materials. Overloading can lead to catastrophic failure. Make sure to calculate the total expected load and distribute it evenly across platforms. For heavy-duty applications, ADTO’s high-strength modular scaffolds offer superior load-bearing performance, helping contractors stay both productive and compliant with safety regulations.

6. Secure All Connections and Locking Mechanisms

Modular scaffolding is known for its easy and quick assembly — but that convenience should never come at the cost of safety. Each connection point must be properly locked, pinned, or fastened according to the manufacturer’s design. Loose fittings can lead to instability and collapse. After assembly, perform a thorough inspection to ensure all locking mechanisms are fully engaged.

7. Ensure Proper Access and Egress

Safe access is essential for efficient work. Always install ladders, stair units, or built-in access frames that allow workers to move up and down easily. Climbing the scaffold frames directly is dangerous and not recommended. ADTO Scaffold provides modular systems with integrated ladder frames and stair towers, ensuring easy and secure movement between levels.

8. Maintain Clear Zones Around the Scaffold

Keep the area around the scaffold clear of debris, tools, and unnecessary materials. This not only prevents tripping hazards but also allows for quick evacuation if an emergency arises. Erect safety barriers or warning signs around the base to prevent unauthorized access. Maintaining a clean, organized work zone is one of the simplest yet most effective safety practices.

9. Monitor Weather Conditions

Environmental factors like wind, rain, or lightning can seriously affect scaffolding safety. Strong winds can destabilize tall modular scaffolds, while wet surfaces increase the risk of slipping. Always check weather forecasts before starting work and avoid using scaffolding during extreme conditions. If the scaffold gets wet, inspect the components again before resuming work.

10. Train All Workers in Scaffold Safety

Even the best equipment can become dangerous in untrained hands. Every worker who assembles, uses, or inspects scaffolding must receive proper training. This includes understanding load limits, assembly procedures, and emergency response measures. Many buyers today prefer suppliers that offer technical guidance and training materials—something ADTO Scaffold is known for. ADTO not only provides high-quality equipment but also helps clients understand best safety practices through expert consultation.

Why Choose ADTO Scaffold for Safe and Reliable Modular Systems

Safety starts with quality, and that’s where ADTO Scaffold stands out. As a leading scaffolding manufacturer and exporter, ADTO offers premium modular scaffolding systems built with precision-engineered steel and advanced welding technology. Their products comply with international safety standards (EN, ANSI, OSHA), ensuring maximum strength, durability, and reliability.

Moreover, ADTO provides customized scaffolding solutions to fit diverse project needs—whether for construction, maintenance, or industrial use. Their comprehensive product range, competitive pricing, and dedicated after-sales support make them a trusted partner for buyers worldwide. When safety and efficiency matter most, ADTO Scaffold delivers both.

Final Thoughts

Setting up modular scaffolding may seem straightforward, but it demands careful planning, inspection, and discipline. By following these 10 essential safety tips, contractors and workers can minimize risks, prevent accidents, and create a safer working environment.

Whether you’re working on a high-rise project or an industrial facility, always remember that safety begins with quality scaffolding. Investing in a reliable system from ADTO Scaffold means investing in long-term safety, stability, and success for every project.