Scaffolding planks, the temporary working platforms on construction sites, are critical for both worker productivity and safety. Their proper installation is not just a matter of following steps—it’s about ensuring a stable, secure surface that protects lives every day. Whether you're using wooden, steel, or composite boards, the core principles of correct placement, secure fastening, and thorough inspection remain the same.

Know Your Planks: Choosing the Right Material

Before installation, it's essential to select the appropriate plank for the job. The most common types are:

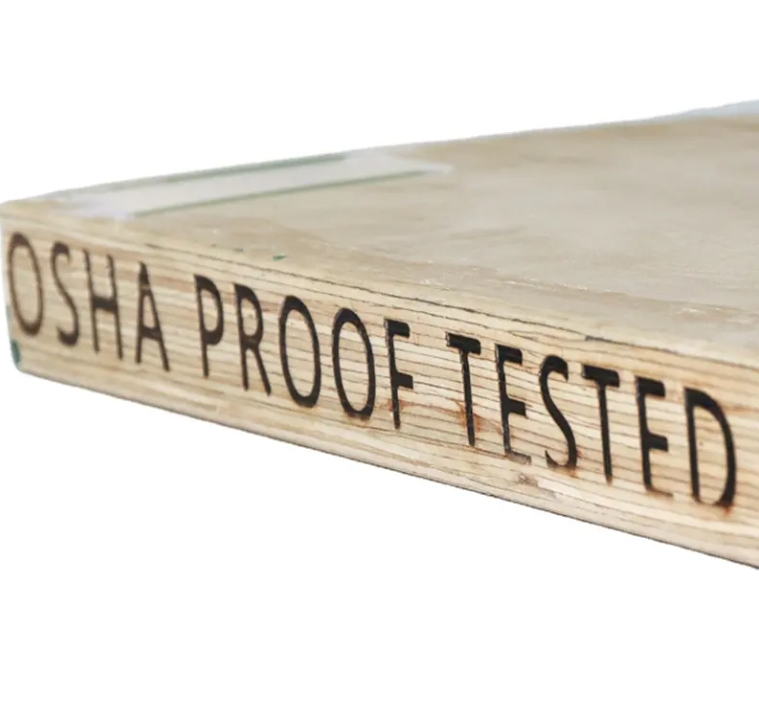

Wooden Planks: Traditionally made from spruce or pine, they are still widely used. A standard wooden plank should be at least 50mm thick and 200-250mm wide. The ends are often reinforced with metal bands to prevent splitting.

Steel Planks: These are durable, fire-resistant, and offer excellent strength. They are typically made from patterned or expanded metal to provide a non-slip surface.

Composite or Plastic Planks: A modern alternative, these are lightweight, resistant to rot and chemicals, and often incorporate a non-slip surface.

Regardless of material, no single plank should exceed a mass of 30kg for safe manual handling.

The Step-by-Step Installation Process

A methodical approach is key to a safe installation. Follow these steps to ensure your platform is built correctly.

1. Preparation and Inspection

Never install a plank that is damaged. Before lifting it into place, check for:

Structural Integrity: Look for cracks, severe warping, or, in wooden planks, deep rot or splitting.

End Condition: Ensure metal end bands (on wooden planks) are secure and not missing.

Surface: The walking surface must be clear of oil, ice, or excessive mud.

2. Placement and Support

Planks must be supported along their entire length by the scaffold’s ledger beams or transoms.

Full Coverage: The work platform must be fully covered with planks. There should be no gaps, except for small, necessary openings which must be guarded.

Adequate Overlap: When planks are laid end-to-end, the joint must occur directly over a support beam. The ends must overlap the support by at least 150mm but not extend beyond it by more than 300mm combined. For a lap joint (where one plank rests on top of another over a support), the overlap should be at least 200mm.

3. Securing and Final Checks

Once laid, planks must be secured to prevent movement.

Fixing in Place: Use appropriate fasteners as per the scaffold system—whether that's clips, hooks, or ties. Planks should not be able to tip or slide when walked upon.

The Final Walk-Through: Before the platform is put into service, conduct a visual and physical check. Ensure every plank is stable, all connections are tight, and the entire platform feels rigid underfoot. The handrails and toe boards must also be in place.

Critical Safety Practices

Installation is just one part of the safety chain. These ongoing practices are non-negotiable:

Competence is Key: Scaffold assembly and alteration should only be carried out by trained, competent personnel. Complex systems like suspended scaffolds require licensed professionals.

Daily Inspections: A competent person must inspect the scaffold, including all planks, before each work shift and after any event that could affect its stability (like extreme weather).

Never Modify or Improvise: Do not use make-shift materials like ladders or loose bricks to extend platforms or level planks. Use only designed components.

Respect Load Limits: Scaffolds have a Safe Working Load (SWL). Do not overload platforms with excessive materials, equipment, or personnel.

Common Mistakes to Avoid

The "Floating" Plank: A plank supported only at its ends, with the middle unsupported, is a major hazard and can break under load.

Unsecured Ends: Planks that are not positively fastened can "kick up" when weight is applied to one end.

Ignoring Small Gaps: Even a small gap between planks can catch a worker's foot, leading to a trip or fall.

Mixing and Matching: Avoid using different types or thicknesses of planks on the same level, as this creates an uneven, unstable surface.

Installing scaffolding planks correctly is a fundamental skill that demands respect and precision. By choosing the right materials, following a disciplined installation sequence, and adhering to rigorous safety standards, you create more than just a work platform—you create a foundation for a safe and productive job site. Remember, when it comes to working at height, there is no room for shortcuts. If you are ever in doubt, stop and consult a qualified supervisor or scaffolder.