For construction buyers and procurement professionals, selecting the right scaffolding accessories is just as important as choosing the main scaffolding system. Among the most essential components in any scaffold setup are Base Jacks and U-Head Jacks. While they may look similar, these two items serve different purposes and play distinct roles in ensuring scaffolding stability and load-bearing performance.

Understanding the difference between base jacks and U-head jacks helps buyers make informed decisions, control project costs, and ensure worker safety. Let’s explore their differences in terms of material, technology, and functional features, and why choosing a reliable supplier—such as ADTO Scaffold—can make a significant difference.

1. Purpose and Function

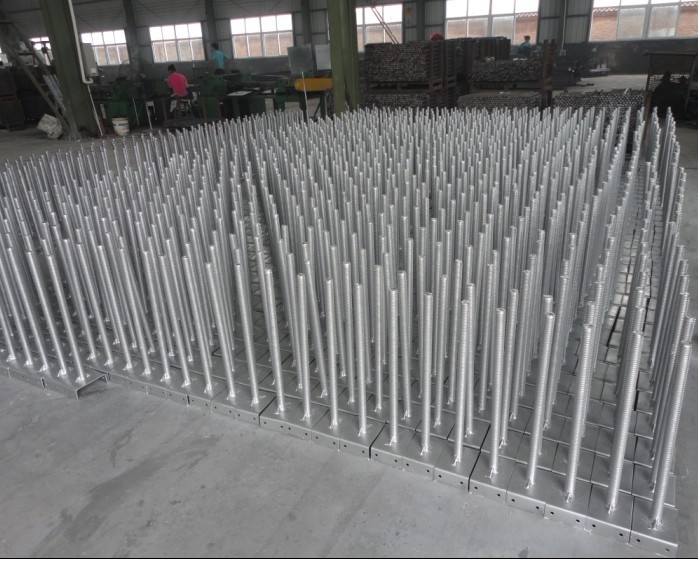

The Base Jack, also known as a Screw Jack or Adjustable Base Plate, is positioned at the bottom of the scaffolding system. Its main function is to provide a stable foundation and allow fine height adjustment to compensate for uneven ground. This ensures the entire scaffold structure stands level and secure.

In contrast, the U-Head Jack is typically used at the top of scaffolding standards to support beams, formwork, or other load-bearing components. The “U”-shaped head cradle holds steel or timber beams in place, offering strong and stable support for slab formwork or shoring applications.

From a buyer's perspective, the difference is clear:

Base Jacks ensure ground stability and vertical alignment,

U-Head Jacks ensure load distribution and upper-level support.

2. Materials and Durability

Both types of jacks are commonly made from high-strength steel, but the grade and finish significantly affect performance and cost.

Material Quality: High-grade carbon steel (such as Q235 or Q345) provides superior load-bearing capacity and long-term durability. Buyers should ensure materials meet relevant international standards to guarantee reliability and safety.

Surface Treatment: Hot-dip galvanization is highly recommended for both base and U-head jacks, as it prevents rust and corrosion, especially in outdoor or humid environments. Although galvanization slightly increases cost, it extends product lifespan, making it a more economical choice in the long run.

A supplier like ADTO Scaffold uses premium steel and advanced galvanizing technology, ensuring both the base jacks and U-head jacks remain durable even after repeated use. For buyers, this means fewer replacements, reduced maintenance costs, and a stronger return on investment.

3. Design and Technological Features

Base Jacks

Base jacks feature a threaded shaft with a solid steel base plate. The screw mechanism allows for precise height adjustment, enabling scaffolders to level the structure easily on sloped or uneven ground. Some models come with hollow or solid stems, depending on load requirements.

Buyers should consider:

Thread type and pitch for smooth adjustment

Base plate thickness for stability on soft or rough terrain

Welding quality to ensure connection strength

U-Head Jacks

U-head jacks are equipped with a U-shaped cradle at the top, designed to hold beams or formwork securely in place. Some come with detachable heads or custom sizes to match various formwork systems.

Buyers should focus on:

Width and depth of the “U” section, ensuring compatibility with beams

Thread precision, which affects load adjustment accuracy

Lock nuts and safety pins, which enhance security under heavy loads

Suppliers who use precision machining and automatic welding, like ADTO Scaffold, deliver jacks with consistent dimensions and superior performance—critical for large-scale or safety-sensitive projects.

4. Choosing a Reliable Supplier

When it comes to purchasing scaffolding jacks, product quality is only part of the equation. Supplier reliability—including production capacity, quality control, and on-time delivery—is equally important.

ADTO Scaffold, a leading global scaffolding manufacturer with over 25 years of industry experience, offers a full range of adjustable base jacks and U-head jacks that meet international standards. Their products are made using high-strength materials, advanced galvanizing techniques, and strict quality inspections.

Buyers also benefit from:

Competitive factory prices through large-scale production

Customization options for different scaffold and formwork systems

Complete quality reports and certificates for each batch

Efficient global logistics and professional after-sales support

With ADTO Scaffold, buyers can trust they are getting products that combine quality, safety, and value.

5. Conclusion

While Base Jacks and U-Head Jacks may look similar at first glance, they serve different yet equally important roles in scaffolding and formwork systems. Base jacks create a stable and level foundation, while U-head jacks provide secure support for beams and structures above.

From a buyer's perspective, choosing the right type—and the right supplier—can make all the difference in ensuring project efficiency, safety, and cost control.

For dependable quality, advanced technology, and excellent service, ADTO Scaffold stands out as a trusted partner for all scaffolding and formwork needs—helping buyers achieve safe, efficient, and cost-effective construction solutions every time.