In modern construction, scaffolding is indispensable for ensuring efficiency, safety, and accessibility in building projects of all scales. Among the many components that make up scaffolding systems, couplers play a central role. These small but vital connectors determine how scaffold tubes join, lock, and bear loads. From the perspective of procurement officers and engineers, the application of scaffolding couplers is a subject that blends technical reliability with cost-effectiveness, influencing both purchasing decisions and on-site performance.

Engineers'Perspective: Technical Importance of Couplers

For engineers, scaffolding couplers are not just accessories but structural linchpins. Their design, material, and manufacturing quality directly affect stability and safety.

Types and Functions

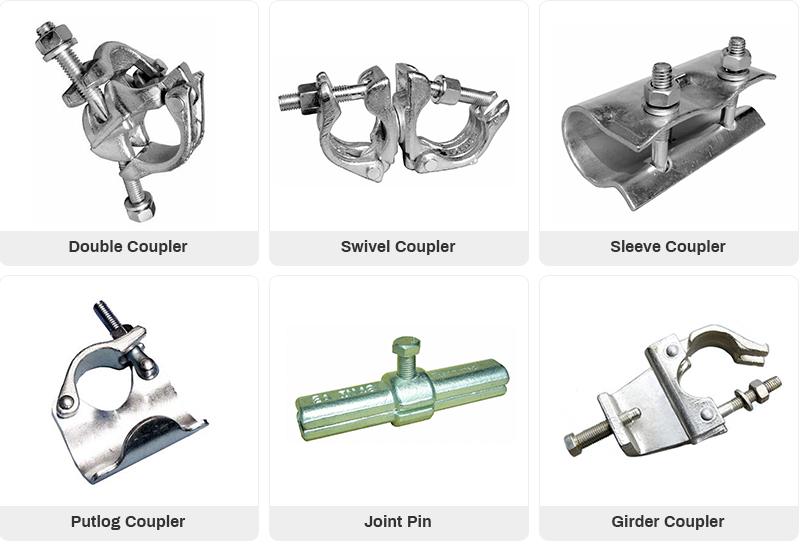

Engineers typically deal with three primary types of couplers:

Right-angle couplers: Essential for joining two tubes at 90 degrees, commonly used for building load-bearing scaffold frames.

Swivel couplers: Provide flexibility by connecting tubes at any angle, crucial for irregular structures or complex geometries.

Sleeve couplers: Used for extending scaffold tubes end-to-end, ensuring continuous strength in longer spans.

Each type of coupler serves a specific structural function, and engineers carefully select the appropriate combination to meet the requirements of the project.

Load-bearing and Safety Considerations

Engineers prioritize couplers that comply with international standards such as EN74 or BS1139. These standards guarantee that couplers can withstand axial, bending, and torsional forces. In high-rise projects or heavy-duty applications, couplers must demonstrate exceptional slip resistance and durability to prevent accidents. A poorly designed coupler can compromise the entire scaffolding system, endangering workers and delaying construction schedules.

Material and Technology

Couplers are commonly made from drop-forged steel or pressed steel, each with distinct advantages. Drop-forged couplers provide superior strength and are preferred for heavy loads, while pressed steel couplers are lighter and suitable for less demanding tasks. Engineers also assess protective coatings, such as galvanization, which enhance resistance to rust and prolong service life in outdoor conditions.

Procurement Officers'Perspective: Cost, Supply, and Quality

Procurement officers approach scaffolding couplers from a business and supply chain standpoint. Their priorities extend beyond technical performance to include pricing, sourcing reliability, and logistics.

Cost-effectiveness

While engineers focus on performance, procurement officers balance quality with cost. Couplers represent a recurring purchase in many projects, so bulk pricing and competitive supplier contracts are vital. However, low-cost couplers that fail under stress can lead to costly site accidents, lawsuits, or reconstruction, making "cheapest is best” an unsustainable approach.

Supplier Evaluation

Procurement officers vet suppliers on several criteria: compliance with international certifications, manufacturing processes, and proven track records. Preference is often given to suppliers who can deliver consistent quality, maintain stock availability, and provide clear documentation of testing and inspection. In large projects, securing couplers from reliable global suppliers ensures smooth project timelines and avoids costly delays due to material shortages.

Packaging and Transportation

Logistics is another critical concern. Couplers are heavy, metallic items that must be transported safely to avoid damage or loss. Well-packaged shipments that optimize container space reduce transportation costs. Procurement officers often negotiate terms to include durable packaging, moisture protection, and organized labeling, making inventory management on-site more efficient.

Intersection of Roles: Collaboration in Decision-making

For scaffolding projects to succeed, procurement officers and engineers must collaborate. Engineers define the technical specifications—such as strength, type, and durability—while procurement officers ensure those specifications can be met cost-effectively and within supply chain constraints.

For example, an engineer may require high-strength drop-forged right-angle couplers for a high-rise construction site. The procurement officer then identifies suppliers who can provide certified products, negotiates favorable pricing, and arranges reliable delivery. This partnership ensures scaffolding couplers perform as required without exceeding budget or delaying schedules.

Conclusion

Though small in size, scaffolding couplers are fundamental to the safety, flexibility, and success of construction scaffolds. Engineers view them as technical essentials that guarantee structural stability, while procurement officers regard them as commodities requiring careful sourcing, cost control, and logistics management. When these perspectives converge, couplers serve their true purpose: enabling safe, efficient, and reliable construction projects. By appreciating both the technical and commercial dimensions of coupler application, construction companies can achieve higher performance and cost-effectiveness in their scaffolding systems.