In the constantly evolving construction industry, walk-through frame scaffolding has maintained remarkable popularity across global markets. From the perspectives of both procurement officers and engineers, this system continues to offer compelling advantages that balance cost efficiency with technical performance, particularly when compared to traditional American scaffolding systems.

The Engineering Perspective: Technical Superiority

From an engineering standpoint, walk-through frame scaffolding demonstrates significant advantages in both design and performance. The system's fundamental innovation lies in its diagonal brace configuration, which incorporates strategic openings that allow workers to pass through safely without climbing over cross braces. This design not only enhances workflow efficiency but substantially reduces fall hazards – a critical consideration in modern safety-conscious construction environments.

The material technology employed in premium walk-through systems represents another area of superiority. Unlike basic American scaffolding that typically uses standard carbon steel, advanced walk-through systems utilize high-strength steel alloys, often S355JR or equivalent grades, with hot-dip galvanization that provides superior corrosion resistance. This material selection results in a stronger, more durable product that maintains structural integrity even after years of rigorous use.

Load distribution represents another engineering advantage. The integrated nodal points in walk-through systems create more efficient load paths compared to the separate couplers and fittings required in American scaffolding. This structural efficiency allows for greater load capacities with less material, translating to both economic and practical benefits on the job site.

The Procurement Perspective: Cost and Operational Efficiency

For procurement professionals, the economic arguments for walk-through frame scaffolding are equally compelling. While the initial investment may be slightly higher than basic American scaffolding systems, the total cost of ownership tells a different story. The modular nature of walk-through systems significantly reduces assembly and disassembly time, directly impacting labor costs – typically the largest expense in scaffolding operations.

Maintenance requirements present another economic advantage. The standardized components and reduced part count of walk-through systems compared to American scaffolding's numerous separate couplers, pins, and fittings means fewer lost components and simpler inventory management. The superior corrosion protection of quality walk-through systems also translates to longer service life and better residual value.

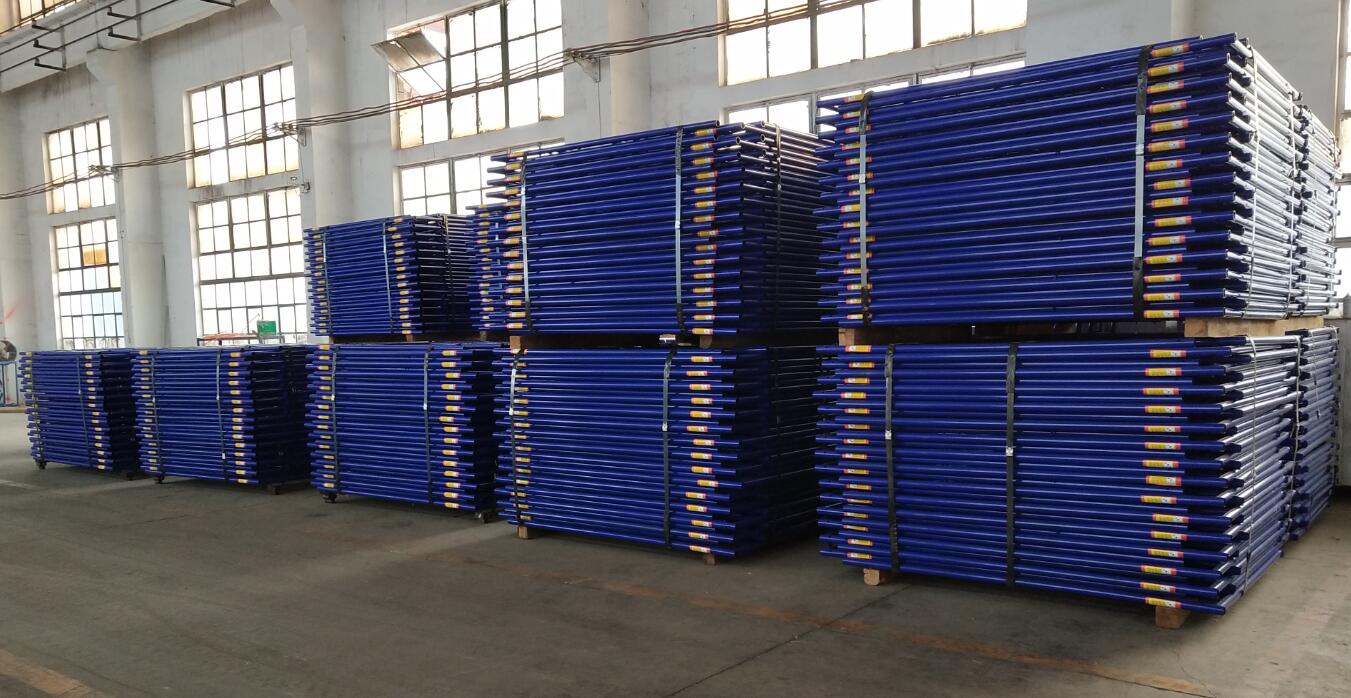

Transportation and storage efficiencies further strengthen the procurement case. Walk-through frames nest compactly for shipping and storage, dramatically reducing the volumetric requirements compared to American scaffolding's separate tubes and fittings. This efficiency extends throughout the supply chain, from reduced warehouse space requirements to lower transportation costs per project.

Why ADTO Scaffold Stands Out

When selecting a scaffolding supplier, ADTO Group has established itself as a leader in both product quality and customer support. For engineers, ADTO offers technically advanced solutions featuring precision laser cutting and robotic welding that ensure consistent quality and perfect fit-up. Their materials meet international standards, with complete certification documentation available for compliance verification.

Procurement professionals appreciate ADTO's comprehensive approach to customer service. The company provides detailed cost-breakdown analyses that help justify investment decisions, along with flexible purchasing options including bulk discounts and leasing arrangements. Their global logistics expertise ensures reliable delivery timelines, while customized packaging solutions minimize damage during transit.

Both engineers and procurement officers value ADTO's commitment to innovation. The company continuously refines their walk-through frame designs based on field feedback and emerging requirements. This results in products that not only meet current needs but anticipate future industry trends, protecting customers' investments over the long term.

Application Versatility

The popularity of walk-through frame scaffolding extends across diverse applications. In commercial construction, the system provides safe, efficient access for facade work and interior finishing. For industrial maintenance, its rapid deployment capabilities minimize downtime in critical operations. The residential construction sector benefits from its simplicity and cost-effectiveness for projects of varying scales.

Compared to American scaffolding, walk-through systems demonstrate particular advantages in projects requiring frequent repositioning or those with repetitive patterns. The system's intuitive design reduces training requirements while maintaining high safety standards – a combination that appeals to both large contractors and smaller specialized firms.

Conclusion

The enduring popularity of walk-through frame scaffolding stems from its successful balance of technical excellence and economic practicality. For engineers, it offers safety, reliability, and performance. For procurement professionals, it delivers cost efficiency and operational advantages. When sourced from a quality supplier like ADTO Group, organizations gain not just superior equipment but a partnership that enhances their overall operational effectiveness.

As construction methodologies continue to evolve, walk-through frame scaffolding remains remarkably well-positioned to meet emerging challenges. Its fundamental design principles align perfectly with the industry's dual objectives of enhanced safety and improved productivity, ensuring its continued relevance in an increasingly competitive marketplace.