In the construction industry, scaffolding is one of the most essential tools for ensuring safe access to elevated work areas. At the heart of any scaffolding system are clamps and couplers—the connectors that join scaffold tubes and provide the framework with its strength and stability. From a buyer's perspective, understanding the key benefits of different scaffolding clamps and couplers is critical for making informed procurement decisions. The right choice ensures safety, project efficiency, and cost-effectiveness.

Right-Angle (Double) Couplers: A Foundation of Strength

Stability and Load-Bearing Capacity

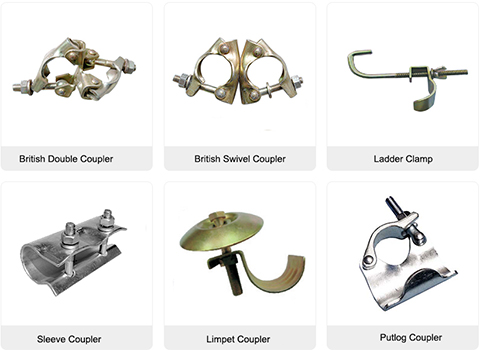

Right-angle couplers, often called double couplers, are the backbone of scaffolding systems. They connect two tubes at 90 degrees, forming strong joints for load-bearing structures. For buyers, this means reliability and assurance that scaffolding will remain stable under heavy loads.

Compliance with Standards

Many right-angle couplers are manufactured to meet international standards such as EN74 or BS1139. Buyers who prioritize certified products can rest assured that they are purchasing safe and regulation-compliant equipment. This reduces risks, potential liabilities, and delays caused by regulatory issues.

Long-Term Investment

Drop-forged right-angle couplers, while slightly more expensive, offer exceptional durability and reusability. Buyers seeking long-term value can save on future replacement costs by investing in these heavy-duty connectors.

Swivel Couplers: Versatility in Design

Flexibility for Complex Projects

Swivel couplers allow tubes to connect at virtually any angle, providing flexibility for non-standard scaffolding designs. Buyers can ensure their contractors have the ability to adapt scaffolds to complex structures such as industrial plants, shipyards, or curved facades.

Broad Application Across Industries

For buyers supplying scaffolding to multiple sectors, swivel couplers are particularly attractive. Their adaptability means one product type can serve a wide variety of applications, simplifying inventory and procurement.

Cost Efficiency Through Adaptability

By enabling scaffold designs that fit irregular structures, swivel couplers reduce the need for custom-made solutions. This adaptability saves procurement costs and provides buyers with better return on investment.

Sleeve Couplers: Extending Tube Lengths Safely

Seamless Tube Extension

Sleeve couplers are designed to connect scaffold tubes end-to-end, extending their length without compromising strength. Buyers benefit from a practical solution for projects requiring long, continuous spans.

Safety in Load Transfer

High-quality sleeve couplers provide strong axial connections, ensuring safe load transfer across extended tubes. From a buyer’s standpoint, this reduces risks of failure and ensures reliable performance in heavy-duty applications.

Reduction of Material Waste

Instead of sourcing longer tubes, buyers can simply purchase sleeve couplers to join shorter ones, lowering procurement costs and reducing waste. This also aligns with sustainability objectives many companies are now prioritizing.

Putlog (Single) Couplers: Lightweight and Cost-Effective

Economical Choice for Non-Load-Bearing Applications

Putlog couplers, also known as single couplers, are ideal for lighter, non-load-bearing connections. For buyers, this offers a more economical option compared to double couplers.

Support for Masonry Work

These couplers are commonly used in putlog scaffolds for brickwork and general construction support. Buyers supplying to contractors in residential or commercial building projects will find them especially relevant.

Simplified Transportation and Handling

Putlog couplers are lighter in weight, which reduces transportation costs and handling effort. Buyers managing large shipments can save on logistics expenses.

Key Buying Considerations

While each type of coupler offers distinct benefits, buyers should keep several overarching considerations in mind:

Quality and Material – Drop-forged couplers provide maximum strength, while pressed steel versions may be lighter and more economical. Buyers should match material choice to project demands.

Certification and Standards – Verified compliance with international standards ensures safety and helps avoid costly legal or regulatory issues.

Supplier Reliability – A trusted supplier with consistent stock, strong packaging, and on-time delivery ensures smooth project progress and prevents costly delays.

Total Cost of Ownership – Beyond the initial purchase price, buyers should evaluate durability, reusability, and transportation savings when making procurement decisions.

Conclusion

Scaffolding clamps and couplers may appear small, but they are crucial in determining the strength, flexibility, and cost-effectiveness of scaffolding systems. From right-angle couplers that guarantee stability, to swivel couplers that provide flexibility, sleeve couplers that extend possibilities, and putlog couplers that offer an economical solution, each type brings distinct advantages. By understanding these benefits from a buyer’s perspective, procurement officers can make informed choices that balance safety, functionality, and long-term value—ensuring successful outcomes for every project.