Scaffold planks are the backbone of any scaffolding system, providing the working platform for laborers, tools, and materials at height. Choosing the right planks impacts safety, efficiency, and project costs. Here's a comprehensive guide to scaffold planks—from materials and types to key advantages and limitations.

What Are Scaffold Planks?

Scaffold planks (also called decking boards or platforms) are horizontal surfaces installed between scaffolding frames or brackets. They must:

Support heavy loads (workers, equipment, materials).

Resist bending, cracking, and slipping.

Comply with safety standards (e.g., OSHA, EN 12811).

Types of Scaffold Planks

1. Wooden Planks

Material: Solid timber (pine, spruce, or hardwood like oak).

Features:

Lightweight and cost-effective.

Require fire-retardant treatment for safety.

Common Use: Residential projects, short-term setups.

2. Steel Planks

Material: Galvanized steel.

Features:

Extreme durability and weather resistance.

Non-combustible; ideal for welding/hot work.

Common Use: Industrial sites, offshore rigs, heavy-load zones.

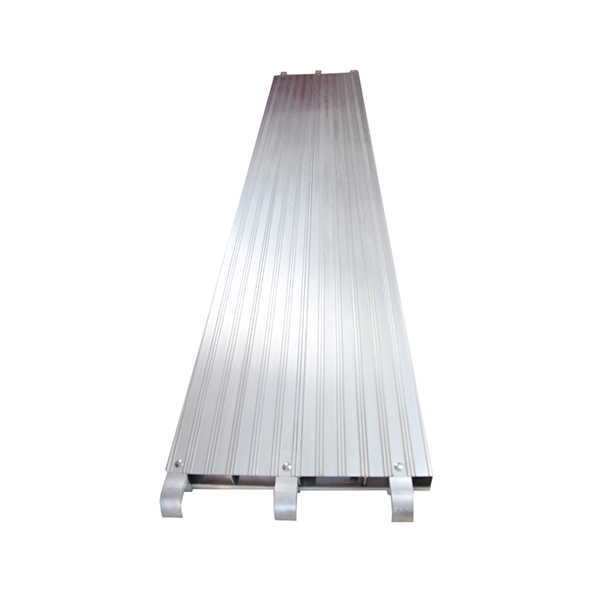

Material: Lightweight aluminum alloy.

Features:

50% lighter than steel, easy to handle.

Corrosion-resistant for coastal/humid sites.

Common Use: Mobile scaffolding towers, frequent repositioning.

4. Composite/LVL Planks

Material: Engineered wood (Laminated Veneer Lumber) or fiberglass-reinforced plastic.

Features:

No splinters, consistent strength, and moisture-proof.

Higher cost but longer lifespan than wood.

Common Use: High-safety environments (e.g., chemical plants).

Advantages of Modern Scaffold Planks

Safety: Non-slip surfaces, guardrail compatibility, and uniform load distribution.

Durability: Metal/composite planks last 10–15+ years vs. wood’s 2–5 years.

Compliance: Meet OSHA load ratings (e.g., light-duty: 25 lb/ft²; heavy-duty: 75 lb/ft²).

Eco-Friendly: Reusable metal/composite planks reduce timber consumption.

Disadvantages & Risks

Wood:

Prone to rot, insect damage, and warping.

Fire hazard without chemical treatment.

Steel/Aluminum:

Higher upfront cost (2–3x more than wood).

Steel is heavy; aluminum dents easily.

Composite:

Most expensive option.

Limited flexibility for curved structures.

Critical Safety Standards

Maximum Overhang: Planks must extend 6–12 inches beyond supports (per OSHA).

Gap Prevention: Joints must align on supports; gaps >1 inch are prohibited.

Load Testing: All planks require regular inspection for cracks, bends, or corrosion.

Non-Slip Surface: Grooved or coated finishes mandatory.